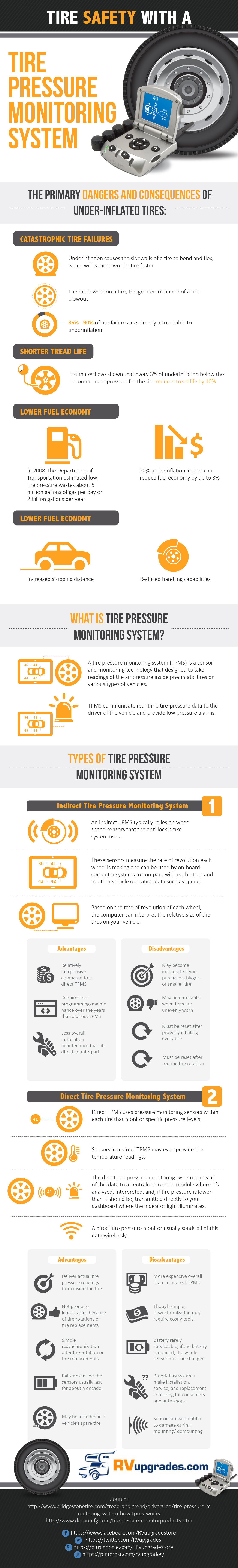

The primary dangers and

consequences of under-inflated tires:

What is Tire Pressure

Monitoring System?

-

A tire pressure monitoring

system (TPMS) is a sensor and monitoring technology that designed to

take readings of the air pressure inside pneumatic tires on various

types of vehicles.

-

TPMS communicate real-time

tire-pressure data to the driver of the vehicle and provide low

pressure alarms.

Types of Tire Pressure

Monitoring System

|